|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Observations on Federal Trowsersby Patrick Brown In this article we will look at characteristics in cut, style, assembly and materials I have found in first hand examination of eighty six original pair of Federal enlisted trousers. About sixty percent were foot trowsers and they were divided about evenly between arsenal and contractor produced. In addition, will consider certain characteristics I believe can be consistently attributed to specific arsenals and makers. I must state here however, that any work of this type must be read with the understanding that we have only a small percentage of the garments produced for the Army during the period considered. Any extrapolation from the specific to the general is risky and must be taken at face value. As one collector said, "...the very fact these items have survived makes them exceptional." The more we learn the more we realize how much we do not yet nor may ever know. Cut and Style

The types are: Type 1: These trowsers have a triangular yoke. Schyulkill Arsenal trowsers are often Type 1.

Materials

The regulations were very specific that the goods supplied be dyed using indigo and no other blue dye. Indigo was the most expensive of the blue dyes. In the 1860's it was almost completely imported from India and the Orient. Not only was the dye itself expensive (and it still is, wholesale it will run you upwards of $3 per once!) but the dying process is very labor intensive. Depending on which process used the vat may need up to one week to be prepared. Pieces of cloth (they were usually anywhere from 10 to 20 yards in length) had to be successively dipped and aired to achieve the desired shade of blue. Depending on the concentration of indigo in a vat and the length the piece is left submerged, sky blue can achieved in three to five dips. Dark blue can take as many as thirty dips for the very dark blue-black colors found in some officer uniforms. Dyeing with indigo is also very imprecise. A multitude of factors, from the Ph of the water, the metal the vat is made from, to the quality of the indigo used can have an effect on how the color comes out. I have yet to run two pieces of wool in an indigo bath and have the results be identical, especially with light blues. In fact, many of the originals I have handled (not just trousers) have pieces that have obviously come from different dye lots as the colors do not match exactly. In one example in particular the waistband was pieced (we’ll talk about piecing below) with half of the waistband several shades lighter than those used on the rest of the garment. I have examined trowsers that certainly look as if they were left in the vat for about one 30 second dip and others that border on a dark royal blue and everything in between. While we are on the subject of color I need to add that the alkali found in indigo vats gives the finished product an almost imperceptible green/gray cast. This is not, as some suppliers of reproduction clothing have claimed because of the, "copperas used as a mordant in the indigo dyeing process." Indigo uses no mordants, but rather it is due to the high alkali content in the indigo dye bath. Look for this in reproduction blue woolen goods. So, and I've been wanting to say this in public for years, those who espouse a "correct" shade of sky blue kersey are simply off their rocker. Look more into the weave (a 2/2 twill with a distinct diagonal weave) than the color. If it is blue with an ever so faint green or better yet a gray cast it is absolutely right no matter how light or dark it is. You may not fancy the shade but that doesn't mean it is incorrect. All this being said, I wondered for many years why on earth the government would be so picky as to insist on an expensive and cumbersome dye for the uniforms of its armies. I found the answer as I dyed the cloth myself using natural dyes including indigo and saw the uniforms I had made from these goods worn and used in the field. First of all indigo is almost completely light fast. It will fade slightly with hard use due to "crocking" (a term describing the loss of color particles adhering to the fibers of the cloth by the friction of normal use) but will not fade in even direct sunlight. Those who have heard the stories of logwood based blues fading to brown in a few weeks use will appreciate this. Second, as stated above it is very durable. It will crock only slightly and even after 130 odd years the loss of color, as far as can be discerned, is very slight and appears to be mostly due to soil adhesion and abrasion. There are modern green based blue dyes that will mimic indigo very well without the cost of natural indigo and are relatively light fast. Even when these do fade they retain many of the characteristics of true indigo dyes. Red based blue dyes are less light fast and do not have the green cast we desire. When red base blue dyes fade they have the dreaded purple cast we all hate to see on ourselves and others. The worst of the red base dyes will turn bright purple with heavy exposure to the sun giving the wearer the fabled purple “Barney suit”. Avoid them like the plague. How do you tell the difference before they fade? Hold the garment in direct sunlight. In direct sunlight the red base dyes will show their “purpleness” even if only faintly.

In addition to the woolen parts, trowsers used cotton or linen lining materials for the fly, waist linings and for the pockets. Generally, unbleached cotton drilling of about 8 oz. to 10 oz. weight was found on most of the originals I have handled. Several had lightweight muslin for the pockets and fly pieces and a few used unbleached linen on the fly facings and pockets. On one pair in the group (a machine sewn Schyulkill Arsenal produced pair) the pockets were made from cotton muslin, the waistband and fly facings from cotton drill and the watch pocket from domit flannel identical to that used on enlisted issue shirts. Contractor variations often used a brown polished cotton-like material as the lining on one or all of the fly pieced for reasons unknown. In addition there was sometimes found a small piece of drilling about 1" square as a reinforcement on the inside of the cuff facings. Often this piece made from a piece of kersey or was omitted entirely. The thread used on the originals in the group varied Both cotton and linen thread was commonly found with linen being the most common. The colors were either dark blue (most common by far), dark gray or black (found on three pair). Many seem to be dyed with a logwood dye and have faded to brown. A good number, about 30%, exhibited dark to medium blue thread that though the garments showed considerable wear the thread has not faded which would indicate a light fast dye other than logwood, possibly indigo. About 90% of the originals I have examined had paper backed tin buttons. Some examples utilized strippled black jappaned tin back tin style while a few had rubber or gutta percha buttons though these may have been replacements. All trowsers utilized larger (about 5/8", though the width varied) buttons on the waistband and smaller (about 3/8") on the fly, though some had what may have been replacement larger size buttons on the fly. Most examples (about 60% of what I have looked at) had only four suspender buttons. Since suspenders were not items of issue in the Civil War there has been some question as to whether some suspender buttons are original or post issue additions. My observations have proven inconclusive. I went looking for evidence such as different thread types or color used on the suspender buttons but I found differing thread on many buttons including fly buttons indicating possible replacement by the soldiers in the field. I did find many differing types of suspender buttons including civilian types on heavily worn examples. I looks as if they popped suspender buttons in the field just like we do now. Go figure. Several pair exhibited damage and repair where suspender buttons had pulled through the material. Finally, only one pair of the trowsers I have examined over the years still had the 1/4" twill tape that was supposed to occupy the split in the back yoke seam. Whether these were removed by the soldier or lost in the years of storage is unknown. Several pair did utilize a small piece of leather thong identical to a piece of shoelace from a pair of brogans in my collection. It is pure supposition and speculation that soldiers used shoelaces when the twill tape was gone/lost but it stands to reason and makes for good lore. Construction Techniques

Piecing of one kind or another was found on a whopping 71% of the trowsers viewed. Piecing is where the tailor economizes by uses multiple pieces of cloth to make one large trowsers piece. It was said of cutters that a good one could pay for himself in a year by economizing on fabric in this and other manners. Because of this one finds a great variation on how the grain of the cloth matched up on the trowsers. Piecing was most commonly found in the crotch, waistband, cuff facings and the seat reinforcements on mounted trowsers.

Flys were set with four, five and sometimes six buttonholes in addition to the single one in the waistband. The number of buttonholes did not show any correlation to size. A brown polished cotton-like material was used on a number of examples on the fly and or fly extensions. In addition to this fly facings made of linen, domit flannel and silk were encountered, albeit in small numbers. Fly linings were almost always set by hand, even on heavily machined examples.

Pockets were side seam on all pieces examined. All examples had topstitching on the front side of the opening and bar tacks to reinforce the opening. The Marine Corps was issued trowsers with french or "mule ear" pockets but there is no evidence of their issue to Army troops. I have, however seen images of infantry and mounted soldiers with this type of pocket and variations. I attribute this to private purchase garments and company tailors busily filling requests to alter the issue garments to fit the individual soldiers' tastes. One problem that existed with the pattern foot trowsers due to the cut of the pocket was that items in the pocket had an annoying way of falling out when one sat or reclined in any way (I encountered the same problem with the OD green sateen army fatigues I wore when on OPFOR duty in the Army). There are examples of foot trowsers with the pockets fixed to remedy this problem. Pockets would either have the opening made smaller or the entry made to come from the top instead of the side.

SizeEarly in the war they were supplied to the troops in only four sizes however so company tailors were designated to alter the mens' uniforms to achieve a smarter fit at a supposedly nominal fee that would come from the soldier's pockets. These tailors were designated as "special duty" and were exempt from certain fatigue duties. One can imagine the work load a company tailor would have had immediately following a general reissue of clothing after a campaign. They would sometimes take advantage of their captive market and charge exorbitant fees. Twenty two of the seventy seven originals viewed showed some signs of alteration, either by a company tailor or the soldier himself. The most common alteration was in the length, though it was common practice to simply roll up the excess length, as period images confirm. Several examples were taken in in the waist at either the side seams or more commonly the back seam. Several examples also exist with back belts that appear to be post production. Later the Army contracted for larger sizes to more realistically accommodate soldiers’ frames.

The Quartermaster Department established sizing norms for trowsers that gave specific measurements for inseam, outseam and waist size. Trowsers came in four sizes initially, with several sizes being added later. The sizes, 1 through 4 ran as follows:

It is my considered opinion, however, that the federal sizing system should be taken only as a general guide in appraising reproduction garments. Research shows that either the measurements provided by the government were either used only as a general guide or makers simply disregarded the system altogether. Whether this was by design or accident is open to debate, but the simple fact remains that based upon the examples left available to us there seems to have been a general disregard for the specifications. This includes items with a pre war provenance. It is also possible that time and heavy use with numerous scouring, scalding and scrubbings in washtubs the trowsers have shrunk and stretched them to different dimensions.

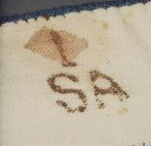

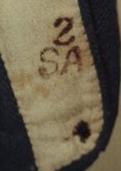

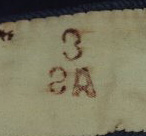

Take into account the following observations of a sample of five pair of foot trousers, all produced by the Schyukill Arsenal, unaltered, size 2 marked "2" over a sans serif "SA":

Note that not one sample adheres to the regulations exactly. Some come close but several are way off, nor does there appear to be any rhyme or reason to the variances. And Finally... I'll conclude with my advice on judging reproduction federal trowsers for your own purchase. Appraisals should be based primarily upon materials, cut and methods of construction. There are certain characteristics common to every original I have examined. Some of them are:

Waistband tapers to the rear becoming noticeably narrower. Pocket openings are set below the waistband. The do not meet or run into the waistband. There is a significant rise of at a bare minimum 2" to 3" in the back. The only topstitching found is on the cuffs, pocket openings and bags and sometimes the watch pocket. The front pieces exhibit a characteristic curve at the outseam. Fly / waistband are usually set by hand, regardless of the amount of machine work on the trowsers.

.*In general, Levi brand 501 style jeans are constructed almost identically to Federal Type 1 trowsers. Of course there are numerous details that vary and the cut and fit are over a century apart, but most of the pieces are generally the same and they go together pretty much the same way. Special thanks to the following: The garments and photographs in this article are from the collections of Steve and Linda Lassiter, Mike Cunningham and the author. All photos are by the author. Line drawings are adapted and used by permission of John Wedeward.

Stragglers

|

|

|

|

|

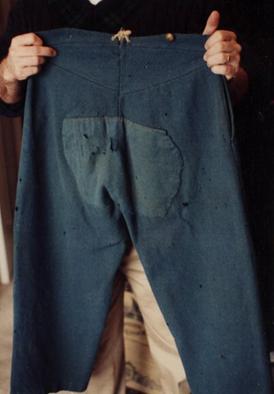

Repairs Repairs were almost as common. The pair below, with a provenance of Confederate use, had the entire seat area replaced. Note also that the sky blue kersey used for the repair did not match that of the trowsers. Also, note the brass Federal eagle service button used as a suspender button on the waistband.

|

||

|

||

|

Additions A number of surviving originals also show signs of fixes that were accomplished to suit the trowsers to the owner’s individual taste. Current research indicates that belt backs were not standard on Federal trowsers. This at least, is definitely a post production addition.

|

||

|

|

|

|

|

There are also these reproductions allegedly made from an original contract piece. The maker claims that they are as issued, so we would be eager to see the supporting documentation. |

The general cut of the trowsers conformed closely with period style, which shouldn't be surprising. The legs were cut full with a distinct curve to the outseam on the front pieces. The waist set high with the waistband settling around the wearer’s natural waistline which is found around the navel. Modern trousers (both mens’ and womens’) are cut so as to settle around the wearer’s hips, much lower than 19th century styles. There was a distinct rise in the back, bringing the back of the waistband well into the small of the wearer’s back. This was the style and would allow a man to wear the trowsers with a short jacket and not leave a gap in back showing his shirt. The seat was baggy, yet not excessively so, which made them particularly comfortable to wear. Belt loops were not to be seen on trowsers until much after the period considered. The size of the waist could be adjusted though, by as much as several inches through use of a split back in the waistband. A ¼” cotton twill tape was set through eyelets sewn into the ends of the waistband in back.

The general cut of the trowsers conformed closely with period style, which shouldn't be surprising. The legs were cut full with a distinct curve to the outseam on the front pieces. The waist set high with the waistband settling around the wearer’s natural waistline which is found around the navel. Modern trousers (both mens’ and womens’) are cut so as to settle around the wearer’s hips, much lower than 19th century styles. There was a distinct rise in the back, bringing the back of the waistband well into the small of the wearer’s back. This was the style and would allow a man to wear the trowsers with a short jacket and not leave a gap in back showing his shirt. The seat was baggy, yet not excessively so, which made them particularly comfortable to wear. Belt loops were not to be seen on trowsers until much after the period considered. The size of the waist could be adjusted though, by as much as several inches through use of a split back in the waistband. A ¼” cotton twill tape was set through eyelets sewn into the ends of the waistband in back.

Regulations specified that kersey be used in the manufacture of trowsers. All examples but one I have examined were made from kersey that varied in weight from 12 and 15 ounces. Variations in weight can be accounted for when one notes the number of suppliers of woolen goods (one in 1857 and 18 by the middle of 1861 alone) to the government. Kersey is woven in a twill weave that is almost always 2/2. It is by definition a heavier cloth and lightly napped which tends to hide the twill until wear exposes it. This nap was apparent on all of the unissued trowsers I have examined and on heavily used examples the nap is gone and the twill in the weave is more readily apparent.

Regulations specified that kersey be used in the manufacture of trowsers. All examples but one I have examined were made from kersey that varied in weight from 12 and 15 ounces. Variations in weight can be accounted for when one notes the number of suppliers of woolen goods (one in 1857 and 18 by the middle of 1861 alone) to the government. Kersey is woven in a twill weave that is almost always 2/2. It is by definition a heavier cloth and lightly napped which tends to hide the twill until wear exposes it. This nap was apparent on all of the unissued trowsers I have examined and on heavily used examples the nap is gone and the twill in the weave is more readily apparent.

Federal trowsers vary from being 100% hand sewn to being almost completely machine sewn. To the best of my knowledge no surviving example exists that is completely machine sewn. Of the trowsers in my study group all but one had the fly, fly extension (the part of the fly on the right hand of the trowsers) and the facings set in by hand. By this process the lining material is not at all visible from the outside. On the single exceptional example, which was contractor produced, the fly extension only was set by machine with the fly proper set by hand. Contractor produced specimens generally exhibit the most machine sewing while some arsenal produced examples, most notably those from the Schyukill Arsenal in Philadelphia, are often entirely hand sewn, though exceptions exist there also. This is not a hard fast rule however. There are contractor examples that are entirely hand sewn and arsenal examples that are heavily machine sewn. The quality of workmanship exhibited on the surviving examples varied greatly. Some were very competently sewn while it’s a wonder others ever passed the inspectors appraisal.

Federal trowsers vary from being 100% hand sewn to being almost completely machine sewn. To the best of my knowledge no surviving example exists that is completely machine sewn. Of the trowsers in my study group all but one had the fly, fly extension (the part of the fly on the right hand of the trowsers) and the facings set in by hand. By this process the lining material is not at all visible from the outside. On the single exceptional example, which was contractor produced, the fly extension only was set by machine with the fly proper set by hand. Contractor produced specimens generally exhibit the most machine sewing while some arsenal produced examples, most notably those from the Schyukill Arsenal in Philadelphia, are often entirely hand sewn, though exceptions exist there also. This is not a hard fast rule however. There are contractor examples that are entirely hand sewn and arsenal examples that are heavily machine sewn. The quality of workmanship exhibited on the surviving examples varied greatly. Some were very competently sewn while it’s a wonder others ever passed the inspectors appraisal.

The waistbands measured from 1 1/2" to 2" at the front to 3/4" to 1” at the back split. There was a noticeable taper on this piece in all specimens. The waistband lining usually extended below the waistband on the inside about 1/2" and was always whipstitched in place. No stitching showed on the outside of the waistbands. The front on the waistband where it met the fly was usually square. Two examples were rounded however. The back ends were divided about evenly between square and rounded styles. The front buttonhole was set somewhat lower than halfway down from the center on the waistband in front on every example viewed. It is not known why as this does not conform to any civilian fashion of which I am aware. Perhaps some reader can shed some light on this mystery.

The waistbands measured from 1 1/2" to 2" at the front to 3/4" to 1” at the back split. There was a noticeable taper on this piece in all specimens. The waistband lining usually extended below the waistband on the inside about 1/2" and was always whipstitched in place. No stitching showed on the outside of the waistbands. The front on the waistband where it met the fly was usually square. Two examples were rounded however. The back ends were divided about evenly between square and rounded styles. The front buttonhole was set somewhat lower than halfway down from the center on the waistband in front on every example viewed. It is not known why as this does not conform to any civilian fashion of which I am aware. Perhaps some reader can shed some light on this mystery. Raw edges were found on all examples inspected but were limited to the pocket facings on most examples. On a few raw edges were found on the fly extensions and pocket openings. One pair is said to exist (I have not personally viewed this pair) with the top edge of the waistband left entirely raw.

Raw edges were found on all examples inspected but were limited to the pocket facings on most examples. On a few raw edges were found on the fly extensions and pocket openings. One pair is said to exist (I have not personally viewed this pair) with the top edge of the waistband left entirely raw.

Cuffs were faced with a separate piece of kersey and had a 1" to 1 1/4" vent placed in the outseam. The cuff vent on Federal trowsers was not a simple split but is set so as to overlap and show no real break when the trowsers lay over the boot or bootee. The facing piece or pieces ranged from 1" to 2" in width and had the upper raw end whipstitched in place. Some examples had both upper and lower sides of the facing left raw and whip stitched but his was rare. The bottom end of the cuffs were topstitched on every piece examined. This was done most often by machine, even on trowsers that were otherwise completely hand sewn. On the inside of the cuff vent there was often a piece of drilling or kersey, whip stitched into place as a reinforcement. The use of kersey to drilling was split about 50/50 with about 25% omitting the piece altogether.

Cuffs were faced with a separate piece of kersey and had a 1" to 1 1/4" vent placed in the outseam. The cuff vent on Federal trowsers was not a simple split but is set so as to overlap and show no real break when the trowsers lay over the boot or bootee. The facing piece or pieces ranged from 1" to 2" in width and had the upper raw end whipstitched in place. Some examples had both upper and lower sides of the facing left raw and whip stitched but his was rare. The bottom end of the cuffs were topstitched on every piece examined. This was done most often by machine, even on trowsers that were otherwise completely hand sewn. On the inside of the cuff vent there was often a piece of drilling or kersey, whip stitched into place as a reinforcement. The use of kersey to drilling was split about 50/50 with about 25% omitting the piece altogether. In addition to the side seam pockets all Federal trowsers had a watch pocket set into the right front at the waistband seam. Only tow variations were encountered in the surviving examples. The most common was a faced type with the facing extending above the waistband. The other, also encountered in high numbers, was a style that had a facing on the interior that did not extend to where it could be seen from the outside.

In addition to the side seam pockets all Federal trowsers had a watch pocket set into the right front at the waistband seam. Only tow variations were encountered in the surviving examples. The most common was a faced type with the facing extending above the waistband. The other, also encountered in high numbers, was a style that had a facing on the interior that did not extend to where it could be seen from the outside.

An experience of my own may shed some light on what I believe may have taken place at least some of the time in the halls used by the inspectors some 130 odd years ago. I was in the process of filling an order for a large group of reenactors that was placed all at one time. There were 21 pair of federal foot trowsers and 27 unlined (and hence unmarked) fatigue blouses. In using an assembly line approach rather than concentrating on one garment at a time as I normally do I found as the order neared completion that the tags I place on garments noting the customers name and information had become detached from most of the blouses as I moved the huge mound from one part of my workshop to another to make room for the trowsers. I had 23 blank sack coats staring back at me defying me to identify their size and owner. The best I could do was try them on myself and match them to the correct size by eyeball and experience. I thought I had done ok but the group's commander later informed me they had their own unexpected historical experience when at a meeting they rolled out the bundle and had to swap and switch until everyone found the coat and trowsers that fit them, just as the troops did in the 1860's. My point is that it is very difficult, even for someone with experience to judge exact size by look alone. I find it hard to believe the inspectors measured each piece of the finished garment as it came from contractors etc. and rejected a perfectly good pair of pants because the inseam was 2" too long or the fly had one buttonhole too few. My personal belief is that they gave the garments cursory glances (lasting say 30 to 90 seconds) and if no glaring defect that would render the garment useable presented itself they smacked their stamp on it and moved on.

An experience of my own may shed some light on what I believe may have taken place at least some of the time in the halls used by the inspectors some 130 odd years ago. I was in the process of filling an order for a large group of reenactors that was placed all at one time. There were 21 pair of federal foot trowsers and 27 unlined (and hence unmarked) fatigue blouses. In using an assembly line approach rather than concentrating on one garment at a time as I normally do I found as the order neared completion that the tags I place on garments noting the customers name and information had become detached from most of the blouses as I moved the huge mound from one part of my workshop to another to make room for the trowsers. I had 23 blank sack coats staring back at me defying me to identify their size and owner. The best I could do was try them on myself and match them to the correct size by eyeball and experience. I thought I had done ok but the group's commander later informed me they had their own unexpected historical experience when at a meeting they rolled out the bundle and had to swap and switch until everyone found the coat and trowsers that fit them, just as the troops did in the 1860's. My point is that it is very difficult, even for someone with experience to judge exact size by look alone. I find it hard to believe the inspectors measured each piece of the finished garment as it came from contractors etc. and rejected a perfectly good pair of pants because the inseam was 2" too long or the fly had one buttonhole too few. My personal belief is that they gave the garments cursory glances (lasting say 30 to 90 seconds) and if no glaring defect that would render the garment useable presented itself they smacked their stamp on it and moved on.