Piecing, a fabric saving techniqe with many applications.

by NJ Sekela

©2003 NJ Sekela

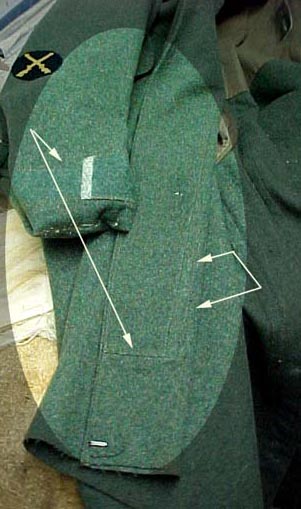

There are many examples of the process practice of piecing sections or unseen parts of garments. I have seen 18th century garments that reflect this process. Of interest, is the fact that piecing continued well into the 20th century. Below is a photograph of a Model 1936 German Overcoat, which was issued from the Berlin depot in 1941. As stated above, the facings, and sleeve bottom (hidden by the fold-back cuff) are pieced by machine. The white streak is actually the selvage edge of a mismatched piece of fabric, which was zig-zagged in place.

German m1936 overcoat with piecing

German m1936 overcoat with piecing

As stated above, this was done to save fabric, but it also indicates, or at leads one to believe that these garments were all cut out by hand. It is widely believed that the band knife was used during the Civil War for larger cutting operations. The problem was, and is to this day, that these items cannot cut small parts, without the fabric shifting. Today, they cut out blocks and die cut the smaller parts.

One should keep in mind, that this was not only a factor of economy, but may also indicate the correction of a mistake. In Louis Devere's The Handbook of Practical Putting on the Centre Point System, (reprinted by R.L. Shep)., he stated on page 121 of his section on inaccurately cut garments,

"The proper way of correcting this fault, is...Join in a piece, so as to raise the side point (or cut fresh side bodies)."

The piecing found in military contract pieces from the Civil War, highlight their crudeness compared to civilian garments. In an english work published in 1840, titled The Tailor, it not only mentions piecing garments, but also "biting up" and "scratching up" the seams of these pieced sections. In essence, they were disguising these pieces, by creating a nap by scratching the fabric with their fingernail or with the needle, and then biting them closed with their teeth.

Piecing still goes on to this day, while actually not to save fabric. There was a shop in New York that did computerized patterns for Liz Claiborne. He produced what was known as a "marker", which is a print out on paper of how the pattern pieces are going to be laid on the fabric. This particular job involved a cape pattern, and he was almost done processing it, when he ran out of paper, and the computer created a line on one side of the cape that wasn't part of the design. He figured that he would add paper to the machine and deal with this after lunch. He reloaded the machine, but forgot to take the line out of the marker. 15,000 garments were cut before the mistake was caught. The person overseeing the project was furious, but succinctly stated, that "we had not choice but to piece them."

Sack coat with pieced body section

The enlisted blouse pictured above is in a private collection in Maryland which I examined this in 1978. It had a one piece sleeve, four piece body, and three piece lining of brown cotton twill. The collar was more squared, which, if one follows the trends of manufacture, usually indicates an earlier garment. Aside from the sleeve lining having shrunk, (drawing the sleeve up), there was nothing that would ear-mark this garment as being condemned. There certainly were no government markings to indicate this. The reason that I believe this is the garment that he is speaking of, because the collector had stated this to me, and had drawn the conclusion that this was rejected by the government, based upon the piecing in the shoulder area. I am enclosing my original photographs taken at the time, which are admittedly dark. In addition, I have included a sketch showing the detail of the shoulder area.

SS private with pieced shoulder area

Upon examination of other garments, it should become clear the government not only accepted piecing in garments, this was and still is a common practice in garment manufacture. There are many reasons for piecing, and one has to interpret the reason, as they are examining the garment. To further illustrate this, is a photograph a Waffen SS soldier, which appeared in Michael Beavers' phenomenal study Uniforms of the Waffen SS, which shows a battlefield pick up tunic, which was originally issued to Wehrmacht soldier, then repaired and reissued to a soldier in the SS. The repairs were done by piecing in new sections of fabric, and, as the author noted, one can clearly see that these were factory done, since the "ghosting" of the previous insignia is still visible.

Upon examination of other garments, it should become clear the government not only accepted piecing in garments, this was and still is a common practice in garment manufacture. There are many reasons for piecing, and one has to interpret the reason, as they are examining the garment. To further illustrate this, is a photograph a Waffen SS soldier, which appeared in Michael Beavers' phenomenal study Uniforms of the Waffen SS, which shows a battlefield pick up tunic, which was originally issued to Wehrmacht soldier, then repaired and reissued to a soldier in the SS. The repairs were done by piecing in new sections of fabric, and, as the author noted, one can clearly see that these were factory done, since the "ghosting" of the previous insignia is still visible.

As stated, to simply state that piecing was done is not enough. One must look into when the piecing occured and for what reasons. My previous quoting of Louis Devere, ONLY applies to custom tailoring, in his section of "misfits". That is to say, after the tailor measures the customer, cuts out the garment, and finds that that it doesn't fit. That section is set aside to customize his patterns to a particular customer. This does NOT apply to the piecing one finds in military garments, where, as others have correctly stated, is used to maximize materials. In terms of piecing at the time of manufacture. In point of fact, this IS represented in the hobby, although people have not recognized it as such. The trousers produced by JT Martin and HF Harkness are all examples of piecing in the seat area. In general, the narrower the fabric was, required the maker to piece in a larger "kite" area in the back. There are several reproductions of JT Martin trousers on the market today. Ones which have a smaller "kite", indicated that the originals were cut from two different widths of fabric.

My approach to the study of these items is different from that traditionally taken. I do not codify them into "Type I's or II's" without viewing them through the lens of industrial manufacture. I began looking at uniforms before I could drive, and took detailed notes. I then wanted to learn how these items were made, and studied tailoring. I then expanded to production patternmaking, and then ultimately (and currently) wholesale manufacture. Stopping at any point along that journey would risk taking these artifacts out of context.